Machine manufacturer Contiweb was an early adopter of PDM/PLM and built an information system that was perfectly geared to his own operation. However, managing that system was becoming increasing risky, prompting them to choose a modern PLM system. “You shouldn’t underestimate that switch; take the time to prepare and build support” , says Jan Egbert Beuving, R&D manager.

Contiweb in Boxmeer, once part of Stork, later part of Heidelberg & Goss and since last year operating independently, develops and builds machines for the graphic industry. It started with roll changers for offset printing lines, first for narrow paper paths and relatively low speeds, later developing towards larger machines for rolls of up to 7,500 kilos and three metres wide with paper path speeds of no less than 18 m/s. In the 1990s, dryers were added which dry the printed paper, airborne, in one second – later also with integrated coolers.

BROADER

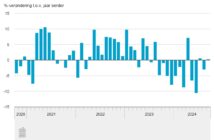

Offset has struggled during this century, partly due to the decline in reading and digitisation. The machines had also become larger and more robust, resulting in a substantial fall in replacement demand. With competitors pulling out, Contiweb now has ninety percent of a shrinking world market in the drying sector. All the more reason to further broaden its offering. For example, the company moved into digital printing, for which it also started developing and building roll changers. Jan Egbert Beuving: “We are now HP’s preferred supplier and have good contacts with Canon-Océ and Kodak, among others.” Contiweb has also started to focus on machines for coating printed/unprinted paper. A milestone was the acquisition of the IP (intellectual property) of the Thallo, which gave Contiweb a foothold in the packaging industry with its own printing line.

STABILISING THE SYSTEM

In this way, Contiweb’s portfolio steadily continued to grow. Of course, R&D (thirty employees out of a total of two hundred) also had to move with the times. While they switched to Siemens’ 3D CAD package NX for the mechanical drawing work twelve years ago, the electrical engineers have been working with EPLAN Electric P8 since 2010. So that the step would not be too big, the company continued using the PDM/PLM system EDM for the management of all schematics, drawings and product data. “We had tailored the software to perfection for our own operation, but we couldn’t keep the system up and running. As far as we know, there are just two people left here who could manage it. We’ve been putting off the switch to another system for a long time.” Last year, the decision was finally taken and Contiweb chose PTC Windchill, with the Belgian company Ad Ultima as their implementation partner. Beuving: “We went live in June, but there are still issues. We had to put all the data that was stored differently in different packages into Windchill. The challenge is to stabilise the system; at the moment, we still have to execute too many tricks to achieve that. Previously, a drawing package would be tested exhaustively before release, so errors were filtered out beforehand. Nowadays that doesn’t happen as thoroughly, so those errors are getting into the system.”

LINKS

The transition to Windchill also offers clear benefits, in particular the digital handling of release and change management, via tasks that

are automatically assigned to employees. “We used to do this physically, with a roll of drawings that made its way between five or six desks. You still had to fill in a form to suggest changes. All the information is now easily retrievable in digital form. Another benefit is that we can connect the Thallo printing press seamlessly to Windchill, with all the data and drawings, even if they were made in SolidWorks. We will be making that link soon.” For the electrical engineering, Contiweb has linked EPLAN’s Electric P8 software to Windchill. “That was done via the EPIS interface package (EPLAN ERP-PDM Integration Suite, ed.), with the help of extensive support from EPLAN. There was a lot we were able to configure ourselves, but EPLAN also modified and configured a number of things for us.” Looking back, Beuving observes that they underestimated the change management: “How you train and prepare people for the transition. I thought, if it works, everyone will be happy. But a lot of people felt completely at home with the old system and were reluctant to move to a new one. So my message is to take even more time to prepare and build knowledge, skills and therefore support among employees.”