OEMs are increasingly focusing on their core business and want everything else in the chain to be taken care of for them. ERIKS is responding to that with knowledgeable and skilled employees, co-engineering and its own rapid prototyping cell. A position higher up in the chain is a win-win: it gives customers and ERIKS itself an edge on the competition.

Holding your own in the battle of the sales channels.

As a service provider in the field of mechanical engineering components, ERIKS serves all the industrial sectors by improving products and processes and ultimately results. The company has more than 450 locations (with its head office in Alkmaar) and 8,000 employees, and is active in 21 countries worldwide. With ever-accelerating developments, high-end customers in the OEM and MRO markets more than anything want other activities to be taken out of their hands so that they can focus on their core activities. ‘And they are looking for savings: which supplier can do A, B, C, D and E at the same time, so that I can let a dozen other suppliers go? You see it at FrieslandCampina and Tata Steel, but also at OEMs like Philips. They are looking for suppliers that will help them improve existing products and develop new products’, says Dennis Boeijer, sales manager for O-rings, Rubber Technology & Dynamic seals at ERIKS.

Dennis Boeijer, Eriks

Supply chain management

A second requirement is speed. ‘Companies want to get to market as quickly as possible, because the shorter the payback period, the better. Our speed in co-engineering makes us an attractive partner, and it keeps us both ahead of the competition.’ He cites the food industry as an example. ‘This industry is subject to all kinds of approvals, standards and laws, requirements which our products must also meet because they may come into contact with foodstuffs. The legislation is constantly changing. For instance, new European legislation came into force last year’, says Boeijer. In order to comply with Regulation EC 1935/2004, ERIKS adjusted dozens of rubber compounds. ‘We perform the tests in our own laboratory, so that we can make the adjustments quickly for our customers – sometimes even before they are aware of the new requirements.’

Reduce

By thinking about customers’ supply chains, ERIKS helps them reduce their Total Cost of Supply and Total Cost of Ownership. ‘For example, by delivering better products that last longer and need to be replaced less often. That saves money. Or by configuring the ordering process more efficiently, so that a company always orders the right component and, thanks to electronic ordering, there are no more errors. It’s about making the customer’s products and processes faster, smarter, safer or more efficient.’

Co-engineering

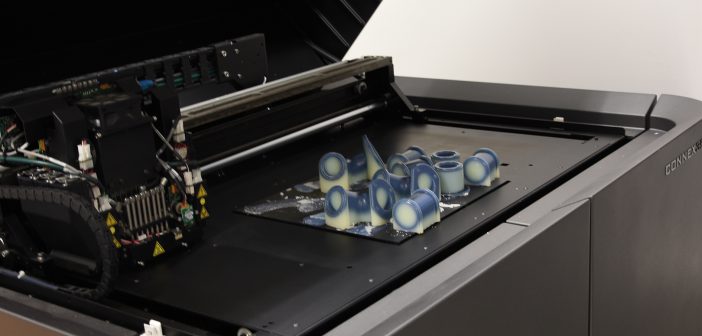

Another aspect that sets ERIKS apart is co-engineering. The extent of co-engineering varies depending on the business unit. ‘My department, Sealing & Rubber Technology, is known in the market for its own brands and its own development using 3D printing. Our approach is born of necessity, since the MRO market alone is not big enough’, says Boeijer. ‘An engineer consults the customer about shape and material. Then a drawing is produced, which he converts into 3D, followed by a 3D print. This sample is installed in the customer’s machine to see if it fits and meet expectations. After approval, we then produce the final product in our own rapid prototyping cell, on which the client can then perform functional tests.’ The process from engineering to testing now takes only two to three weeks to complete; a few years ago, it would have taken three to four months. ERIKS doesn’t mass-produce itself; for that, the company works with manufacturing partners.

Winning

What ERIKS gains from this strategic approach Boeijer illustrates with a practical example. ‘Some time ago, a manufacturer that markets boilers was facing planning problems relating to a rubber hose. A halt to the production line, which produces another central heating boiler every 90 seconds, costs a lot of money’, he explains. ‘The first thing we did was to make sure production would not be interrupted. After that, our engineers were able to solve the problem and offer an improved product within a few days, thanks to our own rapid prototyping cell and 3D printing. If you can do that, you have done 80% of the work of winning over the customer. In the end, this manufacturer awarded the mass production of the hoses to us.’

Flexibility

The ability to respond to customer-specific requirements calls for flexibility, a characteristic generally lacking in big-name brands, says Boeijer. ‘They are trying to get a foot in the door with the big OEMs in the Netherlands too, because that’s where the volumes are. And once you’re in, they’ll come back to you when they are looking for replacements. That is our motivation too. Competitors innovate too, so it is a continuous battle of the sales channels, in which we are trying to stay ahead of web shops and other distributors.’ There is another difference in approach compared to the big-name brands. ‘They mainly try to push their own products, without investigating the problem or exploring other possibilities. The high-tech industry in particular, which has a lot of expertise in rubber compounds and seals, wants its voice to be heard. That is why we are most successful among manufacturers who are facing highly specific requirements. Our co-engineering strategy links in with that seamlessly. New developments in design, products and materials remain our main motivation.