Time-to-market is one of the most important weapons for manufacturing industry as it continues to globalise. For this reason, the OEMs keep on raising the bar for all the suppliers in the chain. That includes the sheet metal companies, which are investing heavily in fully automatic, digitised laser cutters and punching and bending machines. Belgian machine manufacturer LVD is responding to the demand and has seen its markets grow in 46 countries, including the Netherlands.

• ‘Sheet metal working has gone high-tech. You need high-tech machines for that.’

• ‘Machines with an attractive design are the top sellers.’

• ‘The software integration is even more important than the machine.’

• ‘We present ourselves as a supplier and a partner.’

‘One person now does the work of six’

‘The Rolls Royce of machine manufacturers.’ Maurice Hayen, founder and managing director of the sheet metal processing company HLT from Zepperen, near Sint-Truiden in Belgium, is eager to sing the praises of LVD. Not surprisingly, as it was his first customer when he started his company in 2006 and remains one his biggest customers. ‘OK’, he laughs, ‘but by now I have a pretty good idea of what is for sale around the world. It is no coincidence that our assets include bending and cutting machines from LVD.

A lot has changed in the field, says Hayen. ‘We used to think bending a metal plate into a particular shape at four points was complicated; these days, six times that is no exception.’ Expectations have been raised massively. Tolerances of a tenth of a millimetre and three tenths of a degree angular deviation are standard. The slightest deviation in the angle of a bend means rejection. ‘Do you think it is simple to bend a piece of sheet metal into a perfect right-angle? No, it really isn’t, because you always have to account for springback. And that is different for every material, every size and every thickness. LVD manufactures press brakes that can control the process in real time by integrating Easy-Form® laser technology; with built-in laser scanners and the associated software. Sheet metal working has gone high-tech. You need high-tech machines for that.’

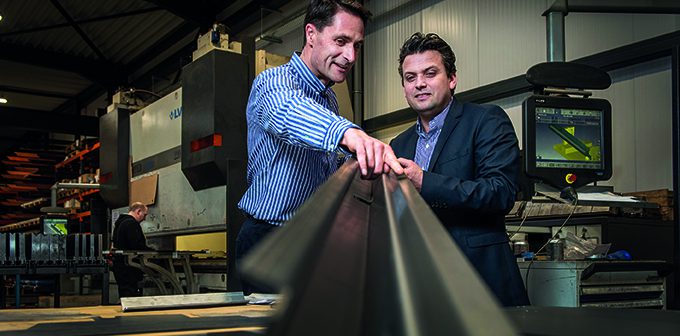

Maurice Hayen en Kurt Debbaut left.: ‘Only companies that digitise will be able to compete.’

Design is important

Kurt Debbaut, product manager and software specialist at LVD, is naturally pleased to hear the words of praise. The more so because he represents a machine manufacturer that is tightening the screws on its supplier. ‘We build laser cutters, press brakes, shears and punching machines for manufacturing industry’, he explains. ‘We use HLT for some of the casings and enclosures. The bar is indeed high. We want top quality, casings that fit exactly, with just the right recesses for the control panels, and no seams or bumps.’ And preferably nicely finished, too, because we want to please the eye: a survey among LVD’s customers revealed that machines with an attractive design are the top sellers. ‘Is design really important for a machine that produces parts somewhere in the workshop? Apparently so – the customer decides. That’s how it works. We also demand fast, just-in-time delivery at competitive prices. We deliver our machines worldwide and work to very tight schedules. We don’t want to keep parts or enclosures in stock, we want them delivered just-in-time. HLT manages to meet all those requirements.’

Doing more in-house

LVD, which has its head office in Belgium, was founded in 1952 and has 1,250 employees. Due to a small domestic market on the one hand and strong growth ambitions on the other, from the outset LVD was strongly focused on exports and established its own sales offices at strategic locations. LVD now operates in 46 countries, with production facilities in Belgium, Slovakia, the USA and China. LVD is a demanding customer that is cherished by HLT in Zepperen. It represents a solid foundation, but Hayen is not putting all his eggs in one basket. The company strategy is based on growth, which is provided by a fast-expanding customer base in Belgium. The number of employees has risen to 25; last year, they decided to expand the warehouse by over 1,500 square metres. That expansion is almost finished, complete with spray booth. ‘We not only need more space to handle the order flow, we are also going to be doing more in-house. We want to outsource less of the post-processing – such as milling, welding and coating. Customers are demanding more and more ready-to-use products, but at competitive prices. Outsourcing sheet metal for painting means high logistics costs, risk of damage and lost time. That is why we are going to be doing more in-house.’

Software integration

In order to avoid wasting time, Hayen decided to extensively automate production – in partnership with LVD. Last year, a new laser cutter was installed and integrated into the production line. ‘We cut a lot of sheet metal using the laser. But it’s not just a matter of incorporating a cutting machine. The software integration is much more important. By linking the ERP system to the LVD software, we can now generate a quote immediately and practically fully automatically on the basis of a digital drawing. By linking all the data, including from the production department, we know exactly what the costs are and we can make very accurate subsequent costings – for the material to be used, but also for the set-up and effective hours that the machines will be running, the time that the welder is working on the product and the time it takes to coat and paint it.’ In the old situation, the planning engineer had to look up everything every time, now the data is available instantly. ‘With the customer’s permission, the same data is used by our own work preparation department. Previously, our people would make their own design, which is now no longer necessary. All in all, we work a lot more efficiently and hence a lot faster. One person now does the work of six. That frees up time for the others to spend on acquisition, for example. There is plenty of work.’

Saving materials

Another advantage is the more efficient use of materials. ‘We combine the different orders, so reducing waste and enabling us to save over twenty percent on materials. Automating has given us some breathing space to continue to grow and enabled us to get a better picture of all the costs. Calculation is crucial in this business.’

HLT is one of the first sheet metal processors in Belgium to take such big steps. ‘We are seeing this trend in other countries, too, led by the Netherlands’, says Debbaut. ‘I think only companies that digitise will be able to compete. You need sophisticated ICT systems for that, to link together purchasing, sales, billing and production. We present ourselves as a supplier and a partner. Close collaborations, as with HLT, are important to us, because that way we know exactly what is going on in the market, what our customers’ customers want.’

OC Verhulst: ‘Capacity significantly increased, faults down’

Drunen-based OC Verhulst develops and produces air conditioning systems for offices, institutions, factories, rental and the agricultural sector. ‘In all shapes and sizes’, says Hans Wijtvliet, COO at the company with over 120 employees. ‘They are usually commissioned by installation firms. They supply the specifications, including the required capacity and the other conditions. We are building more and more systems customised for individual use. Grilles above workstations that blow hot or cold air, for example, depending on the requirements of the user.’

Custom solutions

Many of the orders received by OC Verhulst, part of Orange Climate BV, involve custom solutions. Following approval of the quotation, all the components and electronics are ordered. ‘We custom-make all the sheet metal for the air conditioning units . We do try to work with standard modules and we also have a range of base cabinets for the smaller applications’, continues Wijtvliet. ‘We work with our own configurator, so that we can very quickly assemble combinations and generate a quotation.’ In addition, OC Verhulst manufactures mobile systems and units for temporary use at festivals, for example, or for drying spaces affected by moisture. Those systems are standard, albeit that they naturally come in different dimensions. ‘All in all, we process about 1,400 steel plates in various thicknesses and materials weekly, from which we manufacture 18,000 different products on average every month.’

Since last year, the plates have been cut to size using a laser cutter from LVD. ‘After ten years, we were in need of a new laser cutter. We compared and evaluated three suppliers and eventually LVD’s Phoenix fibre laser came out on top. We were particularly impressed by the software included. It is linked to our ERP system and to the warehouse system of the German manufacturer Remmert.’

More products

The new laser cutter was installed in April 2018 and has been in full use since last autumn. ‘Implementation takes time’, says Wijtvliet. ‘And there are always surprises. But the bottom line is, we are very satisfied. We have more capacity and make significantly more products than before, because the logistics around the laser cutter are more efficient. The raw material is supplied automatically and it is transported to different pallets immediately after the operation.’

This sorting takes place using a Touch-i4 tablet, which can also be used to validate the cut pieces before sending them to the press brake. ‘Previously, that all took much longer. We now even have capacity to do more cutting work for our sister companies OC Waterloo and Vespi. The number of faults has also been greatly reduced.’ During the commissioning phase, LVD regularly adjusted the software. The final part of the link to the warehouse is currently being completed. A major incidental benefit is a substantial reduction in electricity and nitrogen use. ‘Another step in our automation and optimisation, in other words.’

One more wish

Kurt Debbaut of LVD: ‘The Cadman Suite programming and management software optimises the process flow and hence shortens lead times. Thanks to the integration of our software with the LVD machines and the Remmert warehouse, OC Verhulst has all the tools it needs to work in an integrated, automated and efficient manner in the sheet metal workshop.’

Hans Wijtvliet is satisfied with the partnership, but he still has one wish. ‘It would be nice if a barcode or QR code could be printed or lasered onto the individual metal parts during or just before the lasering. Attaching stickers takes time, as does removing them before coating. We are looking into the options with LVD. I’m looking forward to seeing which solution we come up with. In the metals sector, digitisation is never done.’