High-tech industry in Eindhoven and its surroundings is leading the way in technical product innovation, but it is often still characterised by traditional low-volume batch production. Manufacturing innovation with a focus on the social aspect offers a way forward, as shown by the case of Phenom-World with NTS Mechatronics. ‘The Netherlands can compete with any country in the world; low-cost intelligent automation is the future.’

Focus on technology and people

Phenom-World in Eindhoven develops and markets table-top electron microscopes. Neighbouring NTS Mechatronics (200 employees), part of the NTS Group, performs the assembly of the various Phenom models. The turnover (€25 million in 2016) of Phenom-World is growing steadily, but the market is challenging, explains CEO Emile Asselbergs. ‘We are a high end table-top supplier and our competitors have only one weapon, price. But in the low-end market segment, which is all about big volumes, we don’t always want to lose the battle on price.’ Prompting Asselbergs to talk to NTS about cost reduction. ‘We thought we had reached the limits in terms of cost. The numbers were rising and there was constant pressure on price’, explains René van Wijk, CEO of NTS Mechatronics. ‘Every year we shaved a bit off the cost price with value engineering, until we had reached the ‘cost of design’ and couldn’t go any lower. In that scenario, moving to a low-cost production country would have been the classic approach. However, that was not an option, because Phenom-World’s objective was to be ‘made in Holland’. We couldn’t reduce hourly wages, so we had to reduce the number of hours required for assembly. However, we still had batch production, featuring lots of changes to the product. A concept like one-piece flow was virtually unknown in our high-complexity, high flexibility, low-volume industry.’

World-Class Manufacturing

The partners decided to bring in an external consultant with knowledge of manufacturing. ‘Someone able to think completely outside the box, drawing on knowledge from other industries, and add manufacturing innovation to the product innovation which this region is known for.’ That person was Hans Verwijs of JHV Interim Management. ‘I did indeed witness a lot of batch production with small lot sizes in the high-tech industry here. There is certainly scope to configure this more efficiently by working in-flow, with low-cost intelligent automation. I learned that from Steven Blom.’ Verwijs therefore decided to involve Blom Consultancy in the assignment for Phenom and NTS. ‘A natural choice because they have such deep roots in Japanese production thinking, more than any other consultancy.’ Steven Blom became fascinated by production at an early age and was immersed in Japanese production philosophy as the first production director of Fuji Photofilm in Tilburg. ‘The Netherlands can compete with any country in the world; low-cost intelligent automation is the future. Batch sizes are getting smaller and we need to move towards one-piece flow, with fewer stocks, reduced space requirements and less waste. The way you keep quality under control with robots in mass production you can also do manually by getting employees to check the previous production step at the next one.’ There is a crucial role reserved for people in this. That social aspect was often lacking in the technical approach of WCM, lean and six sigma, noted Blom. Prompting him to introduce the Japanese concept of monozukuri to the Netherlands. ‘It is about autonomy, connection, meaning and expertise. Monozukuri seeks a balance between technical and social aspects and focuses not only on delivering the product but also on the people performing the production tasks. How do you get people to think about their own roles in the process? When building a line for flow production, you can incorporate the social aspect by introducing daily management in the workplace and small group activities aimed at making lots of small improvements. By removing waste, non-added value, from the production process, you can make big savings in a short space of time.’

From left to right René van Wijk (NTS Mechatronics), Hans Verwijs (JHV Interim Management), Emile Asselbergs (Phenom-World), Alfred Plagge and Steven Blom (both Blom Consultancy) in conversation in front of the WCM planning board (not visible). Behind them is the clean room where NTS assembles Phenom microscopes. Photo: Kees Beekmans

Recipe for success

According to Blom, standardisation is the recipe for success, in order to be able to organise the flow in production efficiently: use as many standard components and modules as possible and add the flexibility, the customer-specific features, to the product late on in the process. However, this does require that the engineers stop making constant changes to the product, because that disrupts the flow. Thus, Phenom-World is now only permitted to change existing products twice a year. ‘It was hard for our engineers to stop meddling’, admits Emile Asselbergs. ‘We had to change our culture.’ That culture, the organisation around the product, is often forgotten when it comes to efficiently organising and standardising production, observes Alfred Plagge, senior consultant at Blom Consultancy. ‘But if you tackle it well, other aspects soon follow. You get questions from facilitating departments that want to be part of the new production configuration; for example logistics, purchasing, warehouse, shop floor planning and also new product launches.’

René van Wijk of NTS Mechatronics cites complete transparency between client and supplier as a precondition for the process of change. ‘Phenom-World people move around freely on our shop floor. We have an interest in the predictability of production and the manufacturability of the product. That is why we make the customer part of our team. We expect just as much of the customer as they do of us.’ Van Wijk also points to the need for cultural change. ‘We thought we had everything under control by measuring the familiar key performance indicators. If the feedback calculation matched the pre-calculation, we had done well. But we were missing potential savings in our pre-calculation. Moreover, we managers had to make a shift from traditional control to a facilitating style of management. Instead of telling employees what to do, we had to start asking them what we could do to help them and give them the space to continuously make improvements. Besides, top-down control is no longer sustainable because our industry, with all its customer requirements and regulations, is too complex for that. We need people to take more responsibility.’

Involvement

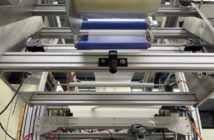

In late 2015, the joint process aimed at efficiency improvement in Phenom’s assembly began; a year later, it started to bear fruit. One-piece flow assembly lines have now been configured for the various Phenom models. The number of assembly hours has been reduced by one third, the total lead time by nearly two-thirds and the quality (yield) has improved by half. Emile Asselbergs: ‘It hugely exceeded our expectations. We invested jointly with NTS and we are now sharing the dividends.’ Alfred Plagge of Blom Consultancy praises the involvement of both managements. ‘Often people will start using a tool for efficiency improvement, work with it for six months and then think the job is done – but of course it’s not like that. I have rarely seen the kind of comprehensive approach to WCM taken in this case.’ Steven Blom: Because René and Emile support the process of change, the employees implement it. That’s monozukuri: people are given a lot of space to do things differently, better. ‘Wow, the boss is listening to us and using our suggestions!’ Employees start putting forward their own ideas, for example to change the layout of the production facility, and the boss merely has to approve them.’ René van Wijk recognises: ‘The commitment and loyalty of our employees has increased because they feel more valued.’ Hans Verwijs describes the cooperation between customer and supplier in this case as exemplary and in particular cites the example of one-piece flow being configured in a clean room, with a clean supply of materials and the removal of finished products. Stocks of materials have been reduced to zero, halving the required floor space, which is of great benefit because square metres in a clean room are expensive.

Chain-wide

The new working method will be rolled out more widely, continues Emile Asselbergs: ‘It means our engineers can focus more on real innovation. We are going to build a pilot plant where new products can bridge the phase between development by our company and production at NTS. There we can apply the final changes to the design, define the bill of materials and draw up the assembly instructions. We will build the first 20 units there, in a partnership between our developers and service people and the NTS production engineers and fitters. Only then will the new products go into the NTS factory and will the process of change stop, aside from those two times per year.’ Apart from that, all parties in the chain are going to coordinate their planning, from the rolling forecast issued by the Phenom-World distributors to the forecast NTS communicates to its suppliers. That commitment is in line with the Japanese philosophy, says Steven Blom.

Incidentally, NTS Mechatronics is not ready to ditch its current Materials Resource Planning in its entirety, reports René van Wijk. ‘We still want the scale model of ordering in bulk, but we will be configuring the supply to us as one-piece flow.’ Blom expects a battle ahead to convince suppliers. ‘For many of them, receiving daily order lists from NTS will take some getting used to.’ Van Wijk: ‘In order to really be able to do it properly, you need to be pretty much vertically integrated and enter into strategic partnerships with external suppliers.’

Eye-opener

Conversely, NTS Mechatronics is already talking to several customers, says René van Wijk: ‘For us, Phenom was a pilot, an eye-opener. We are now extending that to other products and the other NTS companies. In production terms we were a traditional company, we believed that automation was for the high-volume manufacturers. But it turned out that it can also be suitable for high-complexity, high-flexibility, low-volume and that’s the big lesson from this collaboration.’

Article of theLink Magazine Southern Netherlands 2017 Special

Article of theLink Magazine Southern Netherlands 2017 Special