The AdVac® and PER.C6® platform technologies, developed by Janssen Pharmaceutical Companies in Leiden, part of the American pharmaceutical group Johnson & Johnson, are thé tools being used to quickly develop a COVID-19 vaccine, much faster than the eighteen to 24 months that it normally takes, according to Dirk Redlich, Vice President, Head of CMC Development and Clinical Trial Material Production.

The platform, according to his colleague Paul Ives, Senior Director Drug Substance Development, also present in the conference call, is best understood when compared to the platform with which the car manufacturers work: ‘That specifies the configuration of the chassis and on top of that, different bodies can be built, sedan, hatchback or convertible – in our business different vaccine candidate vectors. In 2014-2015 we used the same platform in Leiden to develop the vaccine against Ebola. So a lot of things are already in place, which is why we can now make a lot of speed in the development of a COVID-19 vaccine.’ In this case, ‘speed’ means that the first clinical tests on humans will already take place in September and the first doses of the vaccine used to quell the pandemic could be available for emergency use authorization early next year.

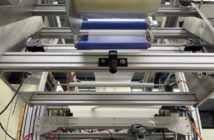

But it is far from over, as both men make clear. Currently the lead candidate vaccine has been selected with the AdVac platform and is being tested in animal models. Parallel to this, production is being scaled up for which the PER.C6 technology is important. This cell line gives a high yield, Redlich points out. ‘Thanks to the high quality of the output, we can quickly scale up our production, from the usual 10 liters to 1000 liters. Within Johnson & Johnson we have the capacity in people and resources available for this. In addition to the production facility in Leiden, we are in the process of setting up one in the US and also in other places in the world.’

THEME: ‘WORKING TOGETHER’ AND ‘SYSTEMS THINKING’ SKILLS MAKE THE SOUTHERN NETHERLANDS RESILIENT. Read the South Netherlands Special digitally

An important part of the development process is data analysis. Johnson & Johnson has invested heavily in precisely that specialism. ‘It is not possible to develop a vaccine without an understanding of the interaction between virus and antibodies. This requires model development for which we use tools such as AI and machine learning. We also use these technologies to develop the production process. We can make a digital version of our factory – a digital twin – and analyse many thousands of data points in it to identify all possible bottlenecks at an early stage.’

Very important is the cooperation of various partners, parties that ensure the supply of, among other things, the basic raw materials, test equipment and single-use materials such as plastic vessels for fermentation processes, Dirk Redlich emphasizes. ‘The cooperation we get from those parties, the willingness to help, is unprecedented. Everyone is committed to delivering what we ask for. I have never experienced the openness with which this happens: the supply chain acts as one organization without company boundaries’, says Redlich, who adds that this not only concerns companies, but also governments and BARDA, the Biomedical Advanced Research and Development Authority. Together with this division of the United States Department of Health, Johnson & Johnson has committed to $ 1 billion investment to develop, clinically test, and produce the COVID-19 vaccine on a large scale. ‘Yes, we are beginning production imminently at risk. But we have already demonstrated many times with our AdVac platform and PER.C6 technology that we can achieve good results quickly.’