From software-only development partner to fully-fledged systems supplier for high-tech OEMs. That is the transformation which Sioux has managed in a targeted and steady fashion over the past five or six years. ‘As a multidisciplinary firm with, we believe, a fairly unique profile, we offer existing and new customers a complete, strong proposition’, so say management team members Ron Willems and Arnoud de Geus. A strong foundation for the next challenge: internationalisation

Software as a foundation for internationalisation

Internationalisation is both a desire and a necessity, according to Ron Willems, director of Sioux’s software division, which includes its growing electronics arm. ‘The Netherlands and Belgium – where Sioux, founded in 1996, has also long been active, ed. – are becoming too small to guarantee a healthy spread of customers. I believe we could easily put all of our 500 engineers to work there – but that would make us very dependent on a few customers.’ Sioux wants to – no, needs to – avoid that, the more so because that would hamper our ambition of significant further growth.

Diversifying strategy

Sioux moved into the German market some time ago. It is particularly active in Bavaria and Baden-Württemberg, which have numerous OEMs specialising in the type of engineering in which Sioux’s added value lies: low volume, high complexity, high precision. Arnoud de Geus, director new business development at the Sioux Group: ‘We are able to play a useful role for various ‘Mittelstand’ OEMs, with say a few hundred million euros in turnover, and we also have a good power balance with them.’ Ron Willems: ‘As a multidisciplinary engineering firm that can also physically deliver and demonstrate its added value, there are opportunities for us there.’

More and more existing – read: primarily Dutch – customers prefer to put the development and assembly of their machines or modules into the hands of a single partner. Linking in with that trend, in 2010 Sioux set out a diversifying strategy which has since been rolled out step-by-step. Today, the Eindhoven system house has all the development disciplines in-house, plus growing capabilities and facilities at the subsequent steps, such as prototyping and testing & assembly (see text box).

Unique profile

Without, emphasises Ron Willems, compromising on what has made Sioux distinctive and great over all those years: software development. ‘In the engineering of complex machines and modules, typically half of the workload is in the software and the other half in the other disciplines put together – and the balance is shifting ever further in favour of software. We see this among just about all our large customers. And the same is now happening in our own business. We are starting to acquire quite a unique profile with the combination of our various development disciplines. There are plenty of system suppliers, but which ones are strong in software development and industrial mathematics? Those are precisely the two areas of expertise we also offer. I believe that that combination is where our strength and uniqueness lie.’

The result: Sioux is carrying out more and more multidisciplinary development projects, albeit always containing a large software component. Ron Willems: ‘In order to be able to tackle them properly, we rejigged our organisation somewhat a little under two years ago. Whereas previously, as a smaller company, we were a single pool, these days we work in discipline-based teams. A matrix organisation from which we can take the people who can deliver the best contributions to a particular development project.’

High-tech assembly

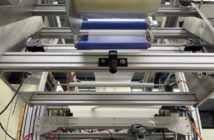

The developers now have short lines of communication to their colleagues with electronics and mechatronics knowledge and expertise, in order to translate a ‘design on computer’ to a product built in-house. As a springboard to this, in 2011 we acquired NBG in Nederweert. Under the name Sioux Manufacturing, this firm builds complete end products and control units – casings, electronics, cabling – for various customers. Ron Willems: ‘Sometimes they can be pretty complex, but mechanically they are not precise down to the nearest micrometre or nanometre. We assemble them in sometimes large numbers, up to several thousand per year.’ One step further: high-tech, low volume machines/modules which do meet the requirements of ultra precision and which Sioux has been assembling at its own production facility including cleanroom since last summer, close to its head office in north Eindhoven. MuTracx (disruptive PCB printers; an acquisition) and Liteq (ditto, lithography packaging machines) have given that facility a flying start, explains Arnoud de Geus. ‘We are now also getting final test & assembly orders from customers for whom we are already doing engineering. That’s the great thing: as a development partner, we can see the direction in which our customers are headed, and as a multidisciplinary partner we can respond proactively.’

Communicating that profile, that strong proposition, to potential customers abroad is Sioux’s challenge. De Geus: ‘Foreign parties, including German ones, are increasingly feeling pressure from Asian competitors, which means they are more open to innovation. With a clear and strong profile, that definitely offers us at Sioux opportunities.’

Article Southern Netherlands issue Link magazine 2017