Cleanliness is a hot topic in the high-tech manufacturing industry. Reason why KMWE took over ATM Oirschot and ATM Mould Cleaning in June last year. ‘The missing link in our process, said CEO Edward Voncken’, adding that significant investments are being made in the cleaning specialist.

KMWE sees a clear increase in the trend of co-engineering with customers

Having visitors is no longer possible now that the Corona virus sows death and destruction in our country. Thus the interview takes place through Microsoft Teams. ‘We use that a lot lately. And we actually quite like it’, says Edward Voncken from the Brainport Industries Campus (BIC) in Eindhoven.

KMWE-ceo Edward Voncken. Photo: Bart van Overbeeke

The specialist in high-precision machining & assembly and supply chain management has ‘not really’ suffered from a major drop in orders, according to Voncken. ‘We do see shifts in the four markets we serve: the civilian aeroplane activities have, as it were, stagnated, but the military aero activities, semicon, healthcare and industrial, are on a par or even increasing. A few months ago, there was still so much demand from customers in commercial aviation that we were short of the military parts in the supply chain. We are now working to eliminate that shortage. So that market mix is more than helping us to keep running at a good level.’

Manufacturability

Apart from the Corona misery, Voncken has for some time seen the clear trend that the contribution of tier 1 suppliers, including KMWE, to the product development by their end customers is increasing. ‘Co-engineering, or concurrent engineering (in which different teams develop in parallel, ed.) is increasing thanks to all this advanced digital tooling. As an OEM, if you let your tier 1 participate early in the design phase and provide input, this improves the manufacturability, the time to market, and so on. We therefore see an enormous need for ICT and data, which is now further fuelled by the Corona crisis. Logging in and programming and engineering at home will become increasingly normal. We are preparing for this.’

The role of the manufacturing architect

KMWE employs over 25 engineers and also works closely with engineering agencies. ‘We are looking for a combination with them: they have real system knowledge, we are in the role of, say, the ‘manufacturing architect’. Because we do not design whole machines or subsystems, our strength lies in the industrialisation of the process. So it could happen that we say: ‘Nice idea, nothing wrong with it, but if we design it this or that way, it is better, easier and faster to produce and assemble.’ These partnerships, with engineering firms and with design teams at the customer, are becoming increasingly intensive and increasingly multidisciplinary.’

Edward Voncken mentions in this context the Asian supply chain that KMWE is redesigning together with customers who have transferred production from Europe to there. ‘We do that with engineers here and at our location in Malaysia. We are now hiring the first engineers who will arrange this with the customer.’

Missing link

High mix, low volume, high complexity; the manufacturing companies and tier 1s in the Brainport region are good in this. According to the KMWE CEO, this is about product(assemblies) that, for example, must meet very strict accuracy and/or cleanliness requirements. ‘That can be a combination of factors. A product with greater tolerances can be complex after all because there are all kinds of critical following steps involved.’

THEME: ‘WORKING TOGETHER’ AND ‘SYSTEMS THINKING’ SKILLS MAKE THE SOUTHERN NETHERLANDS RESILIENT. Read the South Netherlands Special digitally

Cleanliness

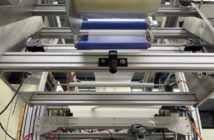

A trend that is also unmistakable is cleanliness. ‘It has to be clean, cleaner, cleanest’, according to Voncken. ‘Of course, OEMs who make complex machines do not want to find out after the machines have been put together that they are internally unclean so that they do not function well – and it is almost impossible to find out which part caused this. So they are industriously looking for ways to measure and test very early in the chain whether each part meets the cleanliness criteria. That is why we took over ATM last June. It specializes in surface treatments and the precise cleaning and packaging of metal parts in smaller series and dimensions. The missing link in our process.’

KMWE has and will continue to invest heavily in that daughter. Among other things, to go even cleaner and to be able to measure it properly, and to increase the cleanroom capacity. ‘We think there is still a lot to be achieved in improving the entire flow of cleaning, smart packaging and shipping.’