Foodfabrikanten kunnen substantieel op productiekosten besparen door een betere controle over de dosering van additieven met de Coriolis instrumenten van Bronkhorst Hightech.

These mini CORI-FLOW™ Series Mass Flow Meters and Controllers distinguish themselves by their capability to measure and control (ultra) low quantities of both liquids and gases, fast and accurately.

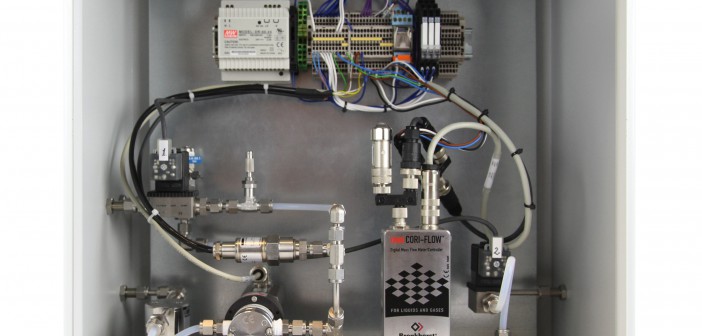

Automating process control allows manufacturers to switch quickly and efficiently between production processes reducing down time and operator involvement. Bronkhorst Coriolis instruments using our own proprietary software, FlowPlot™, or by being added as part of an overall PLC controlled system will add the functionality to include data acquisition capability. Both of these features allow manufacturers to make strides towards better final product quality and consistency while at the same time generating data to allow traceability and quality control.

Standard weigh scale/volumetric methods have many limiting factors that can be both inaccurate and costly. These traditional ways of managing the addition of flavours and colours can require heavy involvement of operator knowledge and experience. This can lead to slow change over times and inconsistent/inaccurate addition of flavours and colours. Making the change to Bronkhorst Coriolis Mass Flow Meters and Controllers, utilizing Cori-Fill™ Technology can bring immediate bottom line rewards to the business.

Bronkhorst Coriolis Mass Flow Meters have the added functionality of directly controlling a secondary instrument required to achieve the end result, either a pump or valve, using our on-board PID control provides quick and accurate response times at flow rates between 0.05 g/hr and 600 kg/hr. Finally, by taking advantage of the control functionality provided by the Bronkhorst on-board PID control the integration of the solution into a current application or manufacturing process is simple and straightforward.